Choosing the best concrete column type for your building isn’t just about structure or design—it’s about balancing safety, cost, speed, and design. From load-bearing capacity to seismic performance and architectural intent, every detail plays a role in how you choose the right column. In this guide, we’ll explore seven widely used reinforced concrete column types, where they work best, their pros and cons, and key design checks based IS 456:2000 code for plain and reinforced concrete and IS 13920 for seismic detailing.

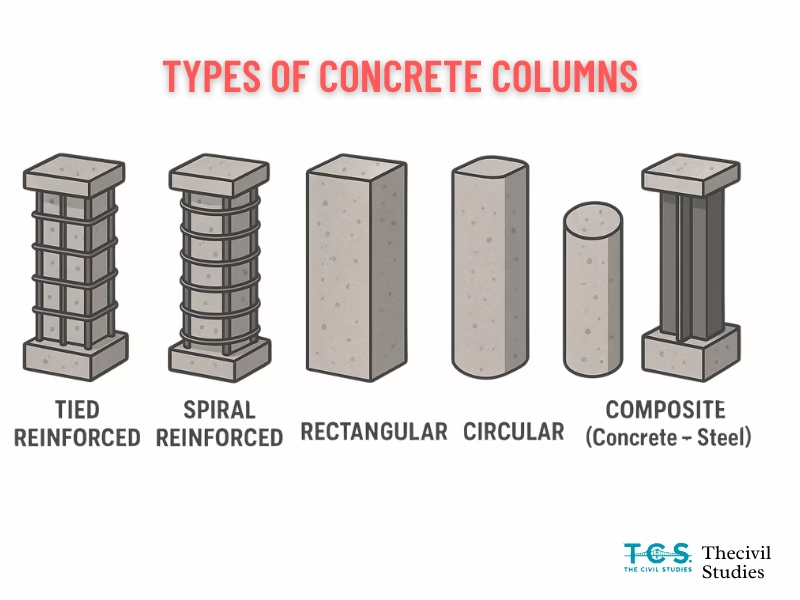

| Column Type | Description & Use Case | Advantages | Considerations |

|---|---|---|---|

| Tied Reinforced Concrete Columns | Concrete columns with vertical bars tied by horizontal stirrups; common in moderate seismic zones and residential/commercial buildings. | Economical, easy to construct, good load capacity. | Requires proper tie spacing to avoid buckling. |

| Spiral Reinforced Concrete Columns | Vertical bars wrapped continuously by spiral reinforcement; ideal for high seismic zones or heavy load-bearing structures. | High ductility, better seismic resistance, improved confinement of concrete. | More complex formwork and construction. |

| Rectangular/Square Columns | Most common shape, easy to form and cast; used extensively in residential and commercial buildings. | Simple shuttering, cost-effective, versatile. | May have stress concentration at corners. |

| Circular Columns | Cylindrical shape, often used where aesthetics or uniform load distribution is important (e.g., curved facades). | Uniform stress distribution, aesthetically pleasing. | More complex formwork, slightly higher cost. |

| Composite Columns (Concrete + Steel) | Steel sections encased in concrete, combining strengths of both materials; used in high-rise and industrial buildings. | High strength-to-size ratio, fire resistance, reduced column size. | More expensive, requires skilled labor. |

| Precast Concrete Columns | Factory-made columns transported to site; speeds up construction. | Faster construction, quality controlled. | Heavy transport, requires cranes and handling. |

| Slender Columns | Columns with high height-to-width ratio; require special design to prevent buckling. | Saves space, suitable for tall buildings. | Needs careful reinforcement and design checks. |

Also Read : Why Your Columns Crack After Casting: Site Mistakes Explained

How to Choose the Right Column Type for Your Building

- Load and Structural Requirements:

- For normal residential or commercial buildings, tied reinforced concrete columns with rectangular sections are practical and economical.

- For high seismic zones or heavy loads, spiral columns or composite columns offer better ductility and strength.

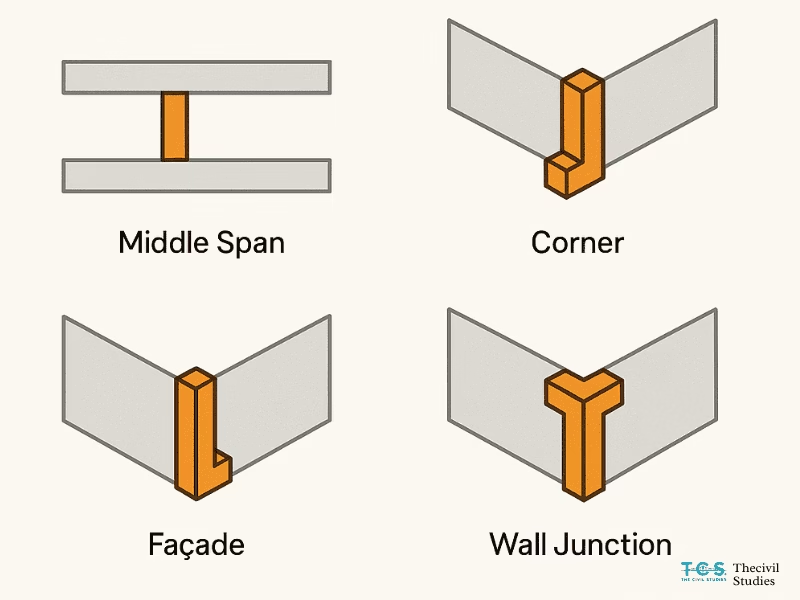

- Architectural and Space Considerations:

- If your design demands curved or slender columns, circular or slender columns are better suited.

- For corner columns or wall junctions, L-shaped or T-shaped columns can be used.

- Construction Speed and Quality Control:

- If time is critical, precast columns can significantly reduce on-site construction duration.

- For complex or high-rise projects requiring high strength and fire resistance, composite columns are preferred.

- Budget and Material Availability:

- Concrete tied columns are generally the most cost-effective.

- Composite and spiral columns involve higher costs but add safety and durability.

Summary Table

| Factor | Recommended Column Type |

|---|---|

| Moderate load, standard construction | Tied Reinforced Concrete Columns (Rectangular) |

| High seismic resistance | Spiral Reinforced Concrete Columns |

| Space-efficient, tall buildings | Slender Columns |

| Aesthetic / curved design | Circular Columns |

| Fast construction | Precast Concrete Columns |

| High strength & fire resistance | Composite Columns (Concrete + Steel) |

References for Further Reading

- IS 456:2000 – Code of Practice for Plain and Reinforced Concrete

- IS 13920 – Ductile Detailing of Reinforced Concrete Structures Subjected to Seismic Forces

- Practical construction guides on column reinforcement and formwork

What is the most suitable type of concrete column for residential buildings?

For most residential and low-rise commercial structures, tied reinforced concrete columns with rectangular or square cross-sections are the most practical choice. They are economical, easy to construct, and provide adequate strength for standard building loads. When designed as per IS 456:2000, they ensure structural stability, durability, and code compliance.

Which type of concrete column is best for earthquake-prone zones?

In seismic zones, spiral reinforced concrete columns are highly recommended due to their superior ductility and energy absorption capacity. The continuous spiral reinforcement confines the concrete core more effectively, enhancing resistance against lateral forces. As per IS 13920 (Ductile Detailing Code), spiral columns outperform tied columns in earthquake conditions.

When should I consider using precast or composite columns in construction?

Precast columns are ideal when construction speed, precision, and factory-controlled quality are critical—such as in modular buildings or time-sensitive projects.

Composite columns (steel encased in concrete) are preferred in high-rise or industrial structures where high strength, reduced column size, and fire resistance are important. Both options require skilled labor and proper handling but offer long-term structural efficiency.

How does IS 456:2000 help in selecting and designing reinforced concrete columns?

IS 456:2000 provides comprehensive guidelines for the design, reinforcement, cover, slenderness, and load-bearing capacity of reinforced concrete columns. It outlines:

Minimum and maximum reinforcement limits

Permissible slenderness ratios

Tie spacing and confinement rules

Load combination principles

Following IS 456 ensures the column performs safely under expected loads and environmental conditions while maintaining structural integrity throughout its life cycle.