Well we knows that the concrete is the most widely used construction material in the world. From small residential homes to massive dams and high rise buildings, concrete plays a very important role in shaping the built environment. But not all concrete is the same. Depending on its composition and use, different types of concrete serve different structural purposes.

we’ll explore:

- What concrete is and why it’s used

- The history of concrete in construction

- Detailed insights into Plain Concrete, Reinforced Concrete, and Prestressed Concrete

- Their composition, strengths, limitations, and practical applications

- Relevant Indian Standard Codes for safe and efficient design

Let’s begin with the basics.

What is Concrete?

Concrete is a composite construction material made by mixing:

- Cement (usually Ordinary Portland Cement),

- Fine aggregates (like sand),

- Coarse aggregates (like gravel or crushed stones),

- And water + (Plasticizer’s as based on special requirement)

Once mixed, this paste undergoes hydration — a chemical reaction that hardens the mixture into a rock-like structure. The result? A strong, durable material that can resist heavy compressive forces and withstand environmental wear.

Evolution of Concrete Use in India

Concrete’s roots go back to ancient India, where early forms of construction during the Indus Valley Civilization (3300–1300 BC) used clay bricks and rudimentary mortars.

India’s journey with concrete took a major turn in 1914, when the country’s first cement plant was set up. In the decades that followed, British engineers made extensive use of concrete in infrastructure — especially in bridges, dams, and public buildings that still define many colonial-era towns. Concrete’s role in shaping dam engineering, in particular, became crucial during this time.

Read how dams evolved in India →

After independence, strict price controls on cement slowed progress. It wasn’t until economic reforms in the 1970s that the industry opened up. With better access to materials, concrete quickly became central to everyday construction — from homes to high-rise buildings.

Explore how concrete transformed modern construction →

Why Concrete is the Backbone of Modern Construction

Key advantages of using concrete in buildings and infrastructure:

- High compressive strength: Ideal for withstanding heavy loads and pressure.

- Versatility: Can be poured into molds of any shape or size.

- Fire resistance: Inherent non-combustible material.

- Low maintenance: Long service life with minimal upkeep.

- Local material availability: Reduces construction costs.

- Wide range of grades – From M5 for non-structural work to M100 for high-performance projects, concrete’s flexibility in mix design allows engineers to meet precise strength requirements.

If you’re working on-site and need help choosing the right mix, here’s a practical guide to M5 to M40 concrete mix ratios that breaks it down clearly.

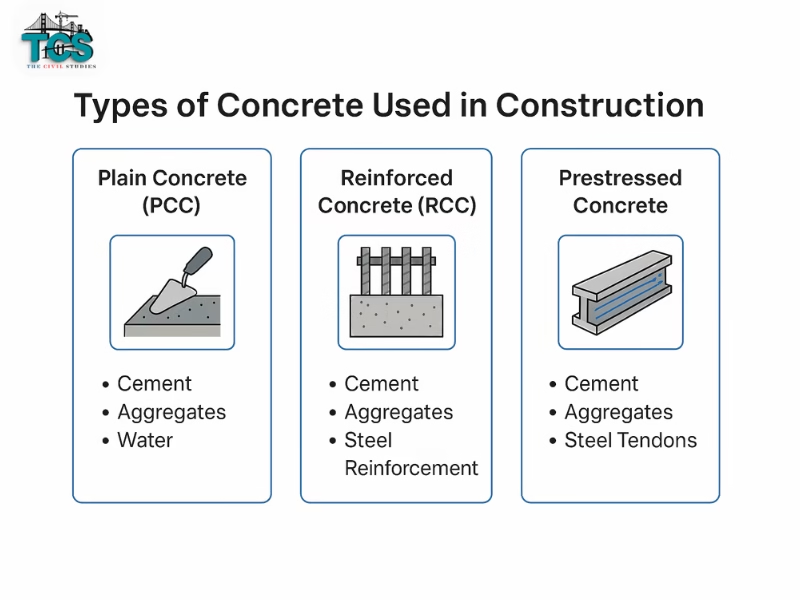

Types of Concrete in Construction

Plain Cement Concrete (PCC)

Reinforced Cement Concrete (RCC)

Prestressed Concrete

Plain cement concrete (PCC) is concrete without any steel reinforcement. It is mainly used in areas where tensile stresses are minimal and compressive strength is sufficient.

When plain concrete is combined with steel reinforcement bars (rebars), it becomes Reinforced Cement Concrete (RCC) — a highly durable and structural material used in nearly all types of load-bearing elements.

Prestressed Concrete is an advanced form of concrete where high-strength steel tendons are tensioned before (or after) the concrete sets, placing the entire section under initial compressive stress.

1. Plain Cement Concrete (PCC)

Plain Cement Concrete (PCC), often referred to as unreinforced concrete, is a basic form of concrete that does not contain any steel reinforcement. It is primarily used in construction elements where the structure is subjected to compressive loads only, with minimal or no tensile stress.

Composition of PCC

The strength and performance of plain cement concrete depend on the quality and proportion of its ingredients. A standard PCC mix includes the following components:

- Cement: Usually Ordinary Portland Cement (OPC) is used as the primary binding material.

- Fine Aggregate: Clean river sand or manufactured sand (M-sand) that fills voids between coarse aggregates.

- Coarse Aggregate: Crushed stones or gravel, typically between 10 mm to 20 mm in size.

- Water: Helps initiate hydration and provides workability for mixing and placing the concrete.

Common Mix Ratio: 1:2:4 (cement : sand : coarse aggregate)

Typical Grades Used: M10, M15, and M20 depending on the load-bearing requirement.

For a detailed breakdown of concrete mix ratios used on-site, see this site guide on M5 to M40 concrete mixes.

Where is Plain Concrete Used?

PCC is best suited for components that carry only vertical compressive loads and don’t experience significant bending, shear, or tension. Its simplicity and ease of use make it ideal for preparatory works and non-reinforced structural parts.

Common Applications of PCC:

- Foundation beds: Used as a levelling course below reinforced concrete footings.

- Flooring slabs: For ground-level slabs in houses, garages, or sheds.

- Pedestals and isolated footings: In columns and machine foundations with light vertical loads.

- Pavement sub-bases: In roads or walkways where tensile stress is not a concern.

- Retaining and gravity walls: When loads are mostly compressive and well-distributed.

- Mass concrete fills: For leveling or filling large voids or trenches.

Limitations of Plain Concrete

Despite its usefulness, plain concrete comes with notable limitations, particularly in structural applications.

- Very low tensile strength: PCC can resist only compressive forces. Its tensile strength is about 1/10th of its compressive strength, making it unsuitable for bending or stretching.

- No ductility: Once the load exceeds its capacity, it fails suddenly without prior warning.

- Cracking risk: Subject to shrinkage and temperature cracks if not properly cured or mixed.

- Not earthquake resistant: PCC lacks ductile behavior, making it unsafe in seismic zones for structural use.

Summary Table:

| Feature | Plain Cement Concrete (PCC) |

|---|---|

| Reinforcement | None |

| Primary Strength | Compressive only |

| Common Mix Ratio | 1:2:4 |

| Grades Used | M10 to M20 |

| Best Suited For | Footings, slabs, non-load bearing walls, levelling layers |

| Not Suitable For | Beams, slabs, or structures with tensile/bending stresses |

2. Reinforced Cement Concrete (RCC)

Reinforced Cement Concrete (RCC) is a composite construction material where steel reinforcement bars (rebars) are embedded within plain cement concrete to enhance its ability to resist tensile, shear, and flexural stresses. Widely used across the world, RCC is the structural backbone of buildings, bridges, foundations, and heavy infrastructure.

Why Combine Steel with Concrete?

Concrete by itself is excellent in compression but very weak in tension. To overcome this, steel bars—known for their high tensile strength and flexibility—are embedded inside the concrete matrix. The resulting RCC behaves like a single unit that can resist complex loads including bending, twisting, and lateral forces.

Steel and concrete have similar thermal expansion rates, which means they expand and contract uniformly, reducing internal stress and cracking under temperature variations.

Components of Reinforced Cement Concrete

A properly designed RCC element includes the following key components:

- Steel Reinforcement (Rebars): Usually high-yield strength deformed (HYSD) bars that carry tensile forces and control cracking.

- Concrete Matrix: Made of cement, sand, aggregates, and water, it resists compressive loads and forms the body of the structure.

- Stirrups, Rings & Ties: These are secondary reinforcements used mainly in beams and columns to resist shear forces and prevent buckling of longitudinal bars.

- Concrete Cover: A protective layer between steel and the surface that prevents corrosion and fire damage.

Key Design Considerations in RCC

Designing an RCC structure requires careful calculations by structural engineers to ensure safety, stability, and serviceability. They consider:

- Rebar diameter and spacing: Based on bending moments, axial loads, and shear.

- Cover thickness: Usually 20–50 mm depending on exposure conditions.

- Load distribution: How loads transfer through slabs, beams, and columns.

- Seismic detailing: Especially in earthquake-prone zones as per IS 13920.

All designs follow national standards like IS 456:2000 and IS 13920 for ductile detailing.

Properties of Reinforced Concrete

Reinforced concrete offers a balanced combination of strength, durability, and versatility. Its performance can be tuned by adjusting mix ratios, rebar detailing, and curing techniques.

Notable properties of RCC:

- High Load-Bearing Capacity: Can resist compressive, tensile, and shear forces simultaneously.

- Ductility: Steel yields before failure, giving early warning signs in structural distress.

- Stress Compatibility: Concrete and steel work together due to similar expansion characteristics.

- Crack Control: Proper reinforcement spacing limits crack widths.

- Fire Resistance: Concrete provides natural insulation to steel bars.

Where is RCC Used?

Reinforced concrete is used in almost every load-bearing and structural component of a building or civil structure. Its adaptability makes it suitable for all types of construction—residential, commercial, industrial, and infrastructure.

Common Applications of RCC:

- Columns, beams, and slabs in framed structures

- Pile and raft foundations for load transfer to deeper strata

- Bridge decks, flyovers, and tunnels

- Water tanks, retaining walls, and reservoirs

- Multi-storey buildings, podiums, and basements

- Earthquake-resistant construction in seismic zones

Limitations and Considerations

Despite its strengths, RCC needs careful planning and protection:

- Corrosion Risk: In aggressive environments, steel may corrode over time. Use proper concrete cover, corrosion-resistant rebars, waterproofing, and admixtures.

- Shrinkage & Cracking: Controlled by correct mix design, reinforcement detailing, curing methods, and use of expansion joints.

- Quality Dependence: Poor workmanship, bad curing, or improper mix can significantly weaken the structure.

3. Prestressed Concrete?

Prestressed concrete is a specialized type of reinforced concrete where high-strength steel tendons or strands are deliberately tensioned before or after the concrete is poured and hardened. This process introduces an initial compressive stress into the structure, counteracting the tensile forces it will face in service.

By preloading the concrete with compression, it becomes significantly more resistant to cracking, bending, and long-span deflection—making it ideal for modern infrastructure.

How Prestressed Concrete Works – Step-by-Step

The key principle is to compress the concrete before it is put into service so it can better handle real-world loads:

- High-tensile steel wires or strands are tensioned using hydraulic jacks and anchored at both ends.

- Concrete is cast around the tensioned steel tendons (pre-tensioned system) or holes/ducts are left for tendons (post-tensioned system).

- Once the concrete gains strength, the tension is released, and the compressive force transfers to the concrete section.

- This internal compression balances the expected external tensile stresses during service, improving strength and performance.

Key Benefits of Prestressed Concrete

Prestressing offers several advantages over conventional reinforced concrete, especially for long-span and load-critical structures:

- Greater Load-Carrying Capacity: Can handle heavier loads with reduced risk of deflection or sagging.

- Longer Spans Without Supports: Ideal for bridges, flyovers, or slabs where intermediate supports are undesirable.

- Minimized Cracks: Pre-compression controls tensile cracking, enhancing durability and water-tightness.

- Material Optimization: Smaller sections can carry larger loads, reducing overall material consumption and cost.

- Improved Structural Efficiency: Suitable for repetitive elements like precast girders, panels, and beams.

Common Applications of Prestressed Concrete in Construction

Prestressed concrete is widely used in large-scale civil engineering and industrial projects where strength, durability, and long spans are essential:

- Railway Sleepers: Designed to resist repeated heavy axle loads over time.

- Bridge Girders and Deck Slabs: Ideal for long spans with minimal intermediate supports.

- Flyovers and Elevated Highways: Used in precast, post-tensioned segments for rapid construction.

- Industrial Sheds & Warehouses: Large clear-span roofs for equipment and storage efficiency.

- Precast Structural Elements: Wall panels, beams, and columns used in modular and high-rise construction.

Pro Tip:

Prestressed concrete is not just about adding more steel—it’s about smarter force distribution. It offers both efficiency and performance, especially in environments where structural deflection or cracking would compromise safety or function.

Important Indian Standard Codes for Concrete Construction

For safe, durable, and efficient concrete design, refer to these IS codes:

| IS Code | Title |

|---|---|

| IS 456:2000 | Code of Practice for Plain and Reinforced Concrete |

| IS 875 (Parts 1–5):1987 | Design Loads for Buildings and Structures |

| IS 1343:2012 | Code for Prestressed Concrete |

| IS 1893:2016 | Earthquake Resistant Design of Structures |

| IS 10262:2019 | Concrete Mix Design Guidelines |

Final Words: Choosing the Right Type of Concrete for Your Project

Each type of concrete—plain, reinforced, and prestressed—serves a unique purpose in construction. Understanding their strengths, limitations, and appropriate applications can lead to safer, more economical, and longer-lasting structures.

Whether you’re building a residential home, a commercial complex, or a highway bridge, the right concrete choice will enhance performance, durability, and safety.

Frequently Asked Questions

What are the key differences between PCC, RCC, and Prestressed Concrete?

Plain Cement Concrete (PCC) contains no reinforcement and is used where only compressive strength is needed—like levelling beds or non-structural flooring. Reinforced Cement Concrete (RCC) combines steel rebars with concrete, offering both compressive and tensile strength, and is ideal for beams, columns, slabs, and foundations. Prestressed Concrete (PSC) goes one step further: high-strength steel tendons are tensioned before or after casting to introduce compression that counteracts tension. This makes PSC perfect for longer spans, heavier loads, and crack-resistant structures. By understanding these differences, engineers and builders can choose the most efficient and durable material for their needs.

2. Which concrete grade (M10, M20, M30, etc.) should I use for different construction elements?

Choosing the right concrete grade depends on structural and functional needs. Low-grade mixes like M10 or M15 (PCC) are used for levelling layers or non-load-bearing sub-bases. For structural RCC components like beams, slabs, and columns, typical grades range from M20 to M40—M20 and M25 are common for residential structures, while M30 and above are used in heavy-duty or prestressed applications. Always refer to IS 10262:2019 for accurate mix design and follow project-specific load requirements.

3. What are the main benefits of prestressed concrete compared to RCC in bridge and slab design?

Prestressed Concrete offers distinct advantages over RCC. Because it is pre-compressed, it can carry heavier loads and span longer distances without additional support or risk of deflection. It dramatically reduces cracking, making structures more durable and water-tight. Furthermore, PSC uses smaller, more efficient cross-sections—reducing material usage and cost. These features make prestressed concrete the preferred choice for modern bridges, elevated flyovers, railway sleepers, and long-span slabs.

4. How are tensile cracks prevented in RCC and Prestressed Concrete?

In RCC, tensile cracks are managed using steel reinforcement and proper detailing—such as placing rebars in tension zones and including stirrups to resist shear. Regular curing and expansion joints also help. In prestressed concrete, however, tensile forces are counteracted before loads are applied. By tensioning steel tendons in advance, PSC ensures almost no tensile stress can form under service loads—making it far superior at crack control and long-term durability.

5. Which IS codes should I follow for designing PCC, RCC, and Prestressed Concrete structures in India?

Ensure compliance with the following Indian Standards:

IS 456:2000 – Code of practice for Plain and Reinforced Concrete

IS 1343:2012 – Code for Prestressed Concrete Structures

IS 10262:2019 – Guide for Concrete Mix Design

IS 875 (Parts 1–5):1987 – Structural load specifications (live, dead, wind, seismic, etc.)

IS 1893:2016 – Seismic-resistant structural design criteria

6. Why is cover provided in RCC?

Cover in RCC refers to the layer of concrete that surrounds the reinforcement bars. It protects steel from corrosion, provides thermal insulation, ensures proper bonding with concrete, and maintains fire resistance. The thickness of cover varies based on exposure conditions and structural elements, as per IS 456:2000.

7. Can RCC be used in water-retaining structures?

Yes, RCC is commonly used in water-retaining structures such as tanks, dams, reservoirs, and swimming pools. With proper water-proofing additives and adequate reinforcement detailing, RCC provides the required strength, impermeability, and durability against water pressure and environmental exposure.

8. What is the standard grade for PCC in construction?

The most commonly used grades for Plain Cement Concrete are M10, M15, and M20. The selection depends on structural needs and the nature of the project. For instance, M15 is widely used for levelling courses, while M10 is typically used for base concrete under foundations.

What is PCC used for in construction?

Plain Cement Concrete (PCC) is primarily used as a foundation bed for reinforced concrete structures. It provides a stable, level surface and prevents direct contact of steel reinforcement with the soil, protecting against corrosion. PCC is also widely used for floorings, simple footings, pavements, and mass concrete works where tensile strength is not critical.