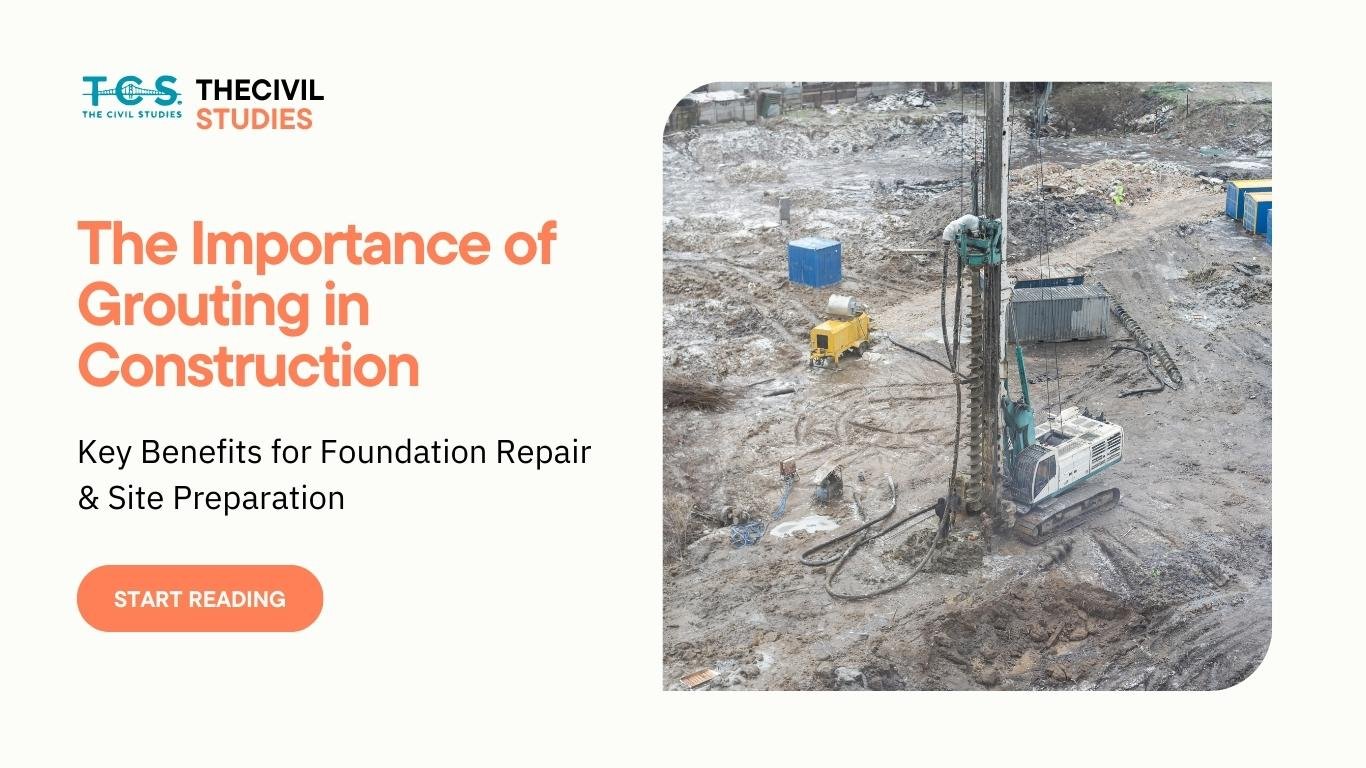

The Importance of Grouting in Construction, Key Benefits for Foundation Repair & Site Preparation

Grouting is one of those behind-the-scenes construction processes that don’t often get talked about—but when done right, it can make or break a structure.

So, what exactly is grouting?

It’s the process of filling gaps, cracks, or voids with a flowable material (usually cement-based or chemical) to strengthen and seal parts of a structure. You’ll commonly see it used under machine bases, around foundations, in soil, or inside old masonry that’s starting to fail.

What is Grouting?

In simple terms, grouting is the process of injecting fluid-like material—often a cementitious, chemical, or resin mix—into voids, cracks, or cavities to improve structural performance. The goal is to fill those empty spaces that could otherwise compromise the integrity of the structure.

Engineer A: “Can’t we just patch it up from the surface?”

Engineer B: “Grouting works from the inside. It’s cleaner, more effective, and gives the structure its strength back without tearing anything down.”

Why Is Grouting Important?

Grouting isn’t just a patchwork solution. It’s a technical method used to improve structural performance without tearing everything apart. When soil settles, concrete cracks, or foundations shift, grouting can be used to restore stability quickly and effectively.

Some of its main roles:

- Increases bearing capacity of foundations

- Prevents water leakage through cracks or joints

- Stabilizes loose soil or voids below slabs and roads

- Reinforces masonry or concrete structures without dismantling them

It’s a favorite among engineers because it’s precise, adaptable, and doesn’t require heavy demolition.

Types of Grouting (and When to Use Them)

Different conditions call for different grouting materials. Here are the most common types used on construction sites:

- Cementitious Grouting:

Made from Portland cement, this is used to fill large voids, cracks in concrete, and soil improvement beneath foundations. - Chemical Grouting (Resins or Polyurethane):

Useful for waterproofing and soil stabilization in fine sands or silty soils. These materials react quickly and work well in tight spaces. - Bituminous Grouting:

Typically used for flexible pavements and waterproofing layers in roads and tunnels. - Epoxy and Resin Grouts:

High-strength, non-shrink grouts often used under machinery bases or in high-vibration areas like industrial plants and bridges.

Where You’ll See Grouting on Site

Grouting shows up in more places than you might think. It’s used in:

- Bridge piers and abutments for additional load support

- Soil stabilization during deep excavation

- Foundation retrofitting for old or underperforming buildings

- Sealing leaks in water tanks, tunnels, or basements

- Dam repair and hydro projects to stop seepage through foundations

Understands It Through An Example

Let’s say a building shows signs of uneven settlement—a corner is sinking slightly. Instead of digging out the entire foundation, engineers inject grout beneath the slab. It fills the voids and lifts the structure back into position.

It’s fast, less expensive, and way less invasive than a full rebuild.

What Should Engineers Know?

If you’re on-site or in training, understanding grout flowability, setting time, shrinkage, and bonding strength is essential. Also consider:

- Grout mix design based on application

- Injection pressure and equipment

- Curing time and how it affects structural loads

- Temperature conditions during application

Lets Concluded it now

Grouting might not look like much from the outside, but technically, it’s one of the smartest and cleanest repair and reinforcement methods available in construction. Whether it’s restoring an old foundation or prepping a site for heavy machinery, grouting offers a reliable way to solve problems without making them bigger.

It’s a subject every civil engineering student, site engineer, or project planner should be familiar with—not just in theory, but in real-world terms.

Discover more from

Subscribe to get the latest posts sent to your email.