During concrete construction projects, it is essential to conduct material testing to ensure quality and consistency. Construction projects are known for their inherent risks, leaving no room for errors in fact, tests like slump testing and other feasibility assessments come into play to prevent failures in construction projects. They help ensure that project standards are met, reducing the risk of problems before the project is completed.

Concrete Slump Test is the common method to measure the workability of concrete, in the previous post we understood it in detail if you missed it then do check out the informative post to know about “Workability of Concrete”; Furthermore, we have already explained in detail the number of factors affecting the workability of concrete such as the water cement ratio, and the gradation of aggregates and mixes used and the procedures for using and placing them.

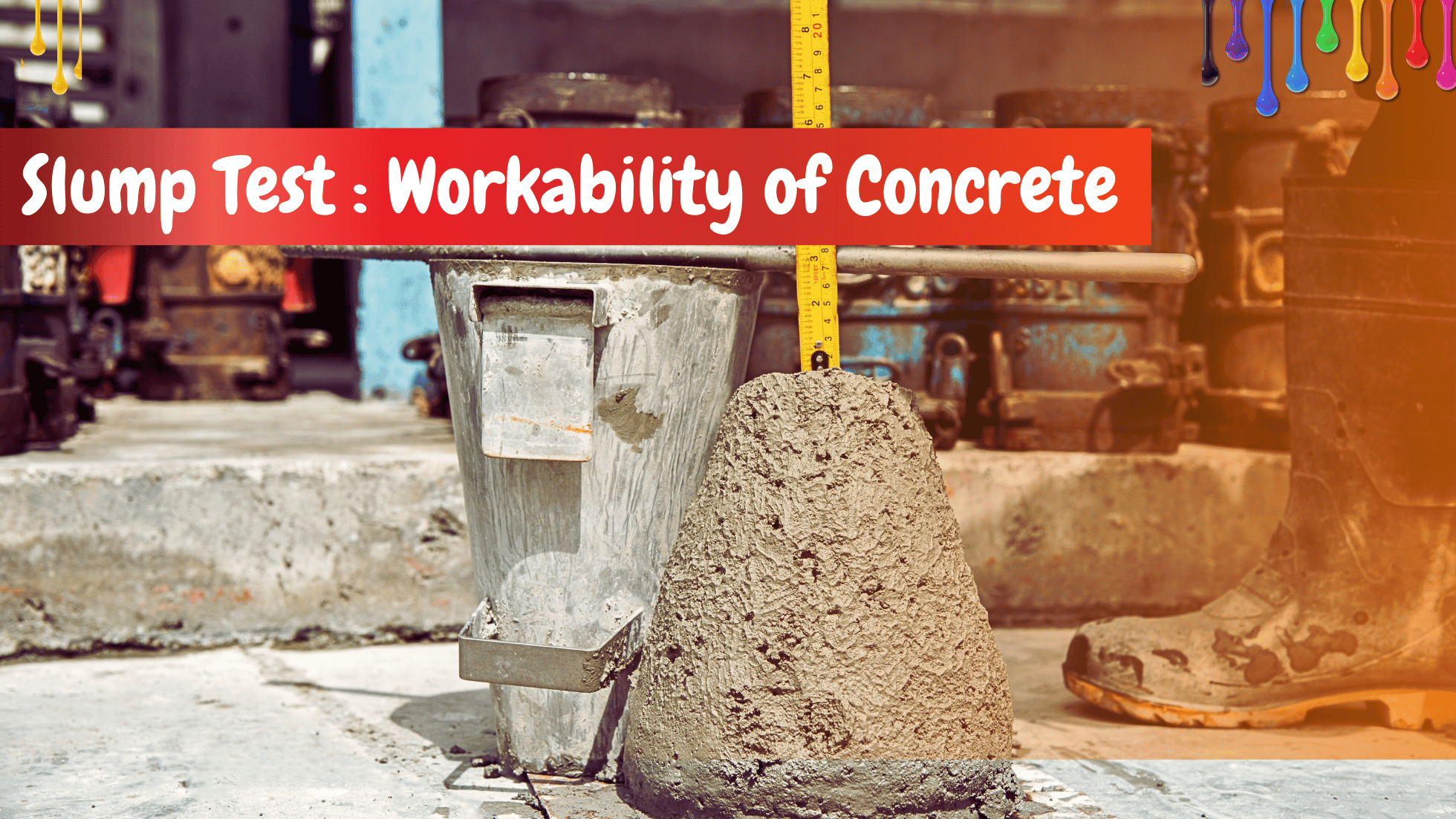

Understanding the Slump Test in Concrete Quality Control

The slump test is done by filling a truncated cone shaped mould with freshly mixed concrete and then removing the mould. Slope is measured as the height difference between the top of the mould and the top of the concrete after removing the mould.

This method can be employed either in a laboratory or at a work site. However, it is not suitable for very wet or very dry concrete mixtures as it may not accurately measure all contributing factors to workability.

What will you lean Post the Article

- Basics of Slump Test

- Understanding the Procedure – Step by Step Guide:

- Advantages and Limitation of Slump Test – Any Concrete Project:

- Things to Keep in Mind During the Test to Overcome Failures

- Key Features

Understanding the Procedure – Step by Step Guide

- Place the mould on a smooth, horizontal, and non-absorbent surface.

- Fill the mould in four layers, with each layer approximately 1/4th of the mould’s height.

- Tamper each layer 25 times using the tamping rod, ensuring even distribution of strokes across the cross-section.

- Immediately remove the mould from the concrete by slowly and carefully lifting it in a vertical direction, allowing the concrete to settle.

- The subsidence of the concrete is referred to as the “slump” of the concrete.

- Measure the difference in levels between the height of the mould and the highest point of the subsided concrete.

What is Shotcrete, Definition, Applications, and its Properties, detailed Concept

Compaction factor test | Workability of concrete

Why cracks are in the Concrete-Detailed Concept -IS Code 456-2000 and SP 25 (1984).

What is Formwork, Definitions, Types and Its Significance

Concrete Thickness Guidelines According to IS 456:2000

| S/N | Type of Concrete Work | Slump In (mm) |

| 1 | Concrete for Rod Construction | 20 to 40 mm |

| 2 | Concrete for Horizontal Structures (e.g., Curbs, Parapets, Piers, Slabs, Walls) | 40 to 500 mm |

| 3 | Concrete for Canal Linings | 70 to 80 mm |

| 4 | Normal Reinforced Cement Concrete (RCC) Work | 80 to 150 mm |

| 5 | Concrete to be Vibrated | 10 to 25 mm |

| 6 | Concrete for Arches and Tunnel Walls | 90 to 100 mm |

| 7 | Mass Concreting | 25 to 50 mm |

| S/N | Nature of concrete Mix | Slump In (mm) |

| 1 | No Slump; 0 mm | Stiff and extremely stiff mix. |

| 2 | Poorly Mobile Mix | 10 mm to 30 mm |

| 3 | Mobile Mix | 40 mm to 150 mm |

| 4 | Normal Reinforced Cement Concrete (RCC) Work | 80 to 150 mm |

| 5 | Cast Mix | Over 150 mm |

Advantages and Limitations of Slump Test in Concrete Projects:

Advantages:

Facilitates Water Content Detection:

Enables easy detection of differences in water content between successive batches of concrete with identical mixes.

Affordable and Portable Apparatus:

The equipment is cost-effective, portable, and convenient for on-site usage, facilitating testing without the need for a laboratory setting.

Limitations:

Limited Workability Correlation:

There is no direct and consistent correlation between workability and the measured slump value, making it inadequate to fully assess workability.

Aggregate Size Constraint:

Not suitable for concrete with aggregates exceeding 40mm in maximum size.

Variability in Slump Shapes:

The test may result in various shapes of slumps, making it challenging to determine the correct value accurately.

Applicability to Plastic Mixes Only:

Slump occurs only in plastic mixes, and the test is not applicable to dry concrete mixes.

Guidelines for Successful Slump Test Execution:

- Proper equipment setup

Make sure that the slump cone, base plate and tamping rod are correctly installed on a stable and level surface to avoid any irregularities during testing.

- Precise Measuring Instruments

Use precision measuring instruments to accurately measure recession, ensuring the integrity of the results.

- Consistent Mixing Technique

Employ a uniform and consistent mixing technique for concrete to maintain uniformity and eliminate inconsistencies in slump results.

- Timely testing

Perform a slump test immediately after mixing to capture the true workability of the concrete, while minimizing the possibility of changes in the mix properties.

- Filling the cone carefully

Fill the slump cone in layers, compacting each layer evenly and avoiding any gaps or air pockets that could affect the slump reading.

- Smooth and uniform tamping

Press each layer evenly and gently to prevent excessive compaction or disruption of the concrete structure.

- Vertical lifting of cone

Lift the slump cone vertically and steadily to prevent lateral movement, allowing the concrete to set without unnecessary disturbance.

- Instant measurement

Measure the slope immediately after lifting the cone to accurately determine concrete subsidence.

- Repeatability and Average

Perform the recession test several times and calculate the average recession value to ensure the stability and reliability of the results.

- record keeping:

Maintain detailed records of each test, including mixing proportions, conditions, and results for future reference and quality control analysis.

Discover more from Civil Studies

Subscribe to get the latest posts sent to your email.

Pingback: Compaction Factor Test | Workability Of Concrete » TheCivilStudies-023

Pingback: What Is Concrete? History | Advanced Technology | OCT - 023

Pingback: Curing Of Concrete: Important Steps For Durable Structures: A Complete Guide » TheCivilStudies

Pingback: What Is Roller-Compacted Concrete (RCC)? » Thecivilstudies

Pingback: Workability Of Concrete: Basic Understanding, Importance, And Testing Methods -2023

Pingback: What Does A 5-Inch Slump Mean In Concrete? » Civil Studies